FDHK-model (1500 - 5000 mm)

Detalles del producto

FDHK-model (5000 - 12000 mm)

Detalles del producto

Rotary Tube Furnace Line for Rare Earth Metals

Detalles del producto

Innovation and continuous improvement is our mission. To provide our customers with the best applicable solution is our goal.

Furnace line for phase transition of uranium oxide consisting of a rotary tube furnace (FDHK-5-500/6000/1000) for drying and heat treatment and a rotary tube cooler (DHK-500/4000/100) for cooling.

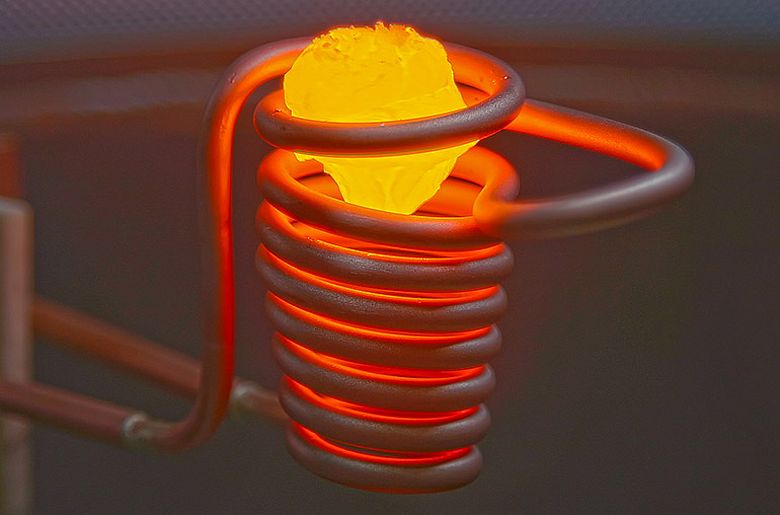

Drying, calcination, heat treatment of bulk goods (powder, granules …) and slurry

Pyrolysis (f.ex. waste, bio mass)Active coal production

Reduction in hydrogen atmosphere (f.ex. U3O8 to UO2)

Linn High Therm is specialized in adapting its products to customer’s requirements. Please let us know if you need any modifications. We will do everything to satisfy your wishes.

| Gama de productos: | special product |

|---|---|

| Modo operacional: | Continous |

| Tipo constructivo: | Dryer, Furnace |

| Diseños: | Rotary tube furnace |

| Temperatura máxima (°C): | 1000 |

| Calentamientos: | electrical |

| Método de calentamiento: | resistance |

| Atmósferas: | Air |

| Aplicaciones: | calcination, drying, oxydation, pyrolysis, reduction |