Наша миссия - инновация и постоянное усовершенствование продукции. Наша первоочередная цель – предложить нашим клиентам наилучшее решение.

Linn High Therm is specialized in customizing its products to customer´s needs. Please let us know if you desire any modifications.

model | liters | Inside dimensions mm (wxdxh) | T. max °C | heating power kW |

|---|---|---|---|---|

LM-322 | 5,1 | 185 x 295 x 95 | 1280 | 2,8 |

LM-422 | 8,4 | 185 x 295 x 155 | 1280 | 3,2 |

LM-522 | 18,9 | 210 x 410 x 230 | 1280 | 8,0 |

The furnace housing as well as the door consists of a mild steel construction. As protection against corrosion the furnace parts are powder coated.

The chosen colours give a nice appearance to the whole furnace. The door is designed as a swivelling door and is mechanically linked with the furnace housing.

The fibre insulation is made from a block of high purity alumina fibre using the vacuum-drawing process, followed by pre-sintered fibre insulation boards.

Due to the fibre insulation materials high thermal power at low energy consumption is achieved. This also results in a low furnace weight.

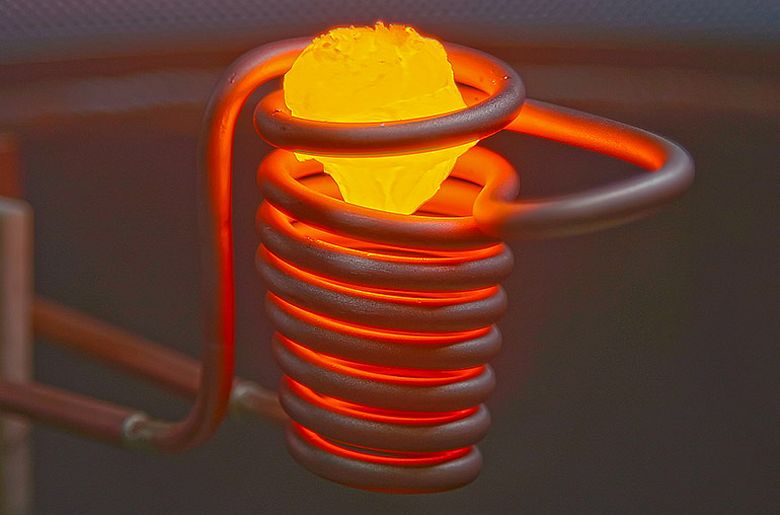

The surface of the SIC muffle is wired with heating spirals, providing a constant temperature distribution inside the chamber. In connection with the insulation extremely short heating up - and cooling down cycles at low heating power will be obtained.

The control system is installed in the lower furnace part. It is equipped with the following components:

- safety controller for overtemperature switch off

- temperature controller with a pre-set heating ramp (Eurotherm 3216)

- switch for heating

- main switch

- controlling thermocouple 2xNiCrSi-NiSi (type “N”)

- for 1280°C version: controlling thermocouple 2xPt13Rh-Pt (type “R”)

- electronic load relay

- door limit switch for cutting power to heating element while door is in open condition.

| Группа товарных изделий: | type series |

|---|---|

| Режим эксплуатации: | Batch |

| Конструктивное исполнение: | Furnace |

| Конструкция: | Chamber furnace, Laboratory furnace |

| Максимальная температура (°C): | 1280 |

| Нагрев: | electrical |

| Метод нагрева: | resistance |

| Атмосфера: | Air |

| Область применения: | annealing, ashing, calcination, firing, fusion, heat treatment, melting, oxydation, pre-heating, sample preparation for spectroscopy, shrink fitting, sintering, soldering, stress-relieving, tempering |