IT-KTV-80/115/1650

Productdetails

MFG-model

Productdetails

Innovation and continuous improvement is our mission. To provide our customers with the best applicable solution is our goal.

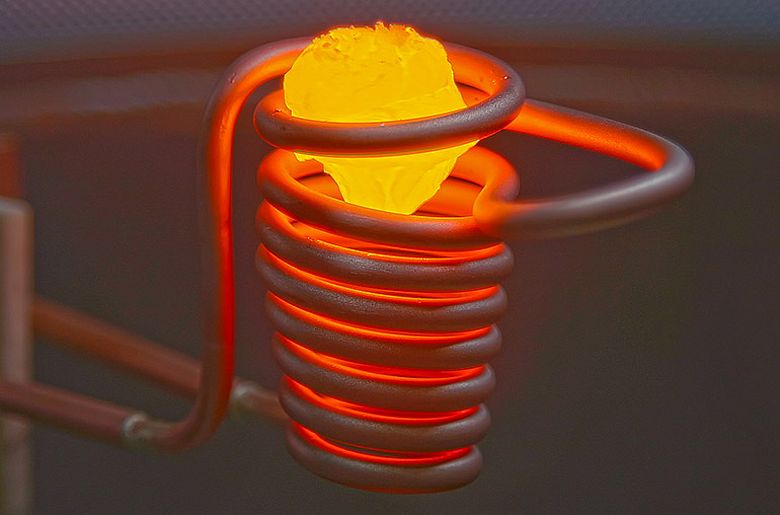

Melting of high purity ferrous alloys

Other possible areas of use could be melting / remelting of stainless steel alloys, Ti, special alloy development

Linn High Therm is specialized in adapting its products to customer’s requirements. Please let us know if you need any modifications. We will do everything to satisfy your wishes.

| Product Line: | special product |

|---|---|

| Operation Mode: | Batch |

| Construction Types: | Melting unit |

| Designs: | Crucible furnace, Remelting unit |

| Temperature Max (°C): | 1650 |

| Heatings: | electrical |

| Heatingmethods: | induction |

| Atmospheres: | Controlled gas atmosphere, Vacuum |

| Applications: | melting, remelting |