Lifumat-Ox-model

Productdetails

Innovation and continuous improvement is our mission. To provide our customers with the best applicable solution is our goal.

Linn High Therm is specialized in customizing its products to customer´s needs. Please let us know if you desire any modifications.

model | outside-dimensions mm (wxdxh) | HF max. kW | Steel | Al | sample sizes |

Lifumat-T-2.4 | 680 x 680 x 1530 | 2,4 | 45g | 20g | Ø 34x 5 mm |

Lifumat-T-4.2 | 920 x 920 x 1530 | 4,2 | 350g | 130g | Ø 60x 15 mm |

Lifumat-T-6.0 | 920 x 920 x 1530 | 6,0 | 650g | 250g | Ø 60x 27 mm |

Lifumat-T-2.4 Vac | 680 x 680 x 1530 | 2,4 | 45g | 20g | Ø 34x 5 mm |

Lifumat-T-4.2 Vac | 920 x 920 x 1530 | 4,2 | 350g | 130g | Ø 60x 15 mm |

Lifumat-T-6.0 Vac | 920 x 920 x 1530 | 6,0 | 650g | 250g | Ø 60x 27 mm |

Lifumat Super | 1500 x 1500 x 2100 | 20,0 (30) | 2000g | 900g | Ø 60 - 120 mm |

Lifumat Super Vac | 1500 x 1500 x 2100 | 20,0 (30) | 2000g | 900g | Ø 60 - 120 mm |

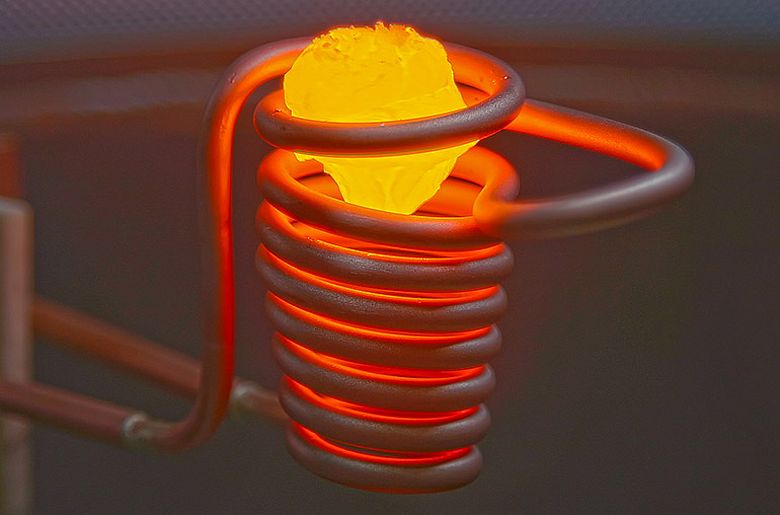

The unit is used for preparation of metallic samples with uniform composition for emission and X-Ray spectrometric analysis, alloy development etc.

It consists of a noise suppressed high-frequency respectively middle-frequency generator with an output power of 2,4 kW – 30 kW and being accommodated in a compact housing together with the induction remelting furnace working under atmosphere resp. vacuum or vacuum with protective gas, and centrifugal casting device with protective gas equipment. The space required is between 0,60 m² and 2,5 m².

The operation is done over a colored touch panel 7” with 10 integrated function keys and integrated PLC function. Decentralized control blocks are used for the control of the machine functions. All inputs and outputs of the sensors and actuators are galvanically isolated and are protectively connected to MF/HF with the decentralized control unit. Process data and process parameters can be read out over an USB interface. An emergency switch, which is well accessible, gives additional safety during operation.

Simple user operation through self-explanatory menu navigation and navigated program flows. Optical visualization of program flow of the respective work steps, program inform over the current status of the machine. Integrated recipe administration for melting programs. Compiled melting programs can be saved easily on a USB stick and implement in further machines of the same types, without having to compile it new.

Safety supervision from various functions with clear text and acoustic alarm emission, for example cooling water temperature, cooling water flow, cover and door locking, generator current (power).

Optical and acoustic signalization in case of failures and at the end of the casting process. Recording of all alarms and faults with date and time stamp.

Safety switch: Magnetic cover locking during casting process, as well as automatic power switch-off when opening the cover during the melting process

Program functions: Atmosphere, vacuum or pre-vacuum with subsequent protective gas flushing up to max. 0,4 bar over pressure (upon request up to 2 bar against surcharge).

User language selectable (German, English, Russian, Chinese = standard, others on request against surcharge).

User level locked interface (manufacturer, administrator, operator)

Free adjustable process parameters in order to optimize processes and compiled melting programs.

Status display of hardware inputs and outputs.

| Product Line: | type series |

|---|---|

| Operation Mode: | Batch |

| Construction Types: | Sample preparation unit |

| Designs: | Remelting unit |

| Temperature Max (°C): | |

| Heatings: | electrical |

| Heatingmethods: | induction |

| Atmospheres: | Air, Controlled gas atmosphere |

| Applications: | casting, melting, remelting, sample preparation for spectroscopy |