Lifumat-M-model

Productdetails

VMK-high temperature-model

Productdetails

Innovation and continuous improvement is our mission. To provide our customers with the best applicable solution is our goal.

Linn High Therm is specialized in adapting its products to customer’s requirements. Please let us know if you need any modifications apart from our standard offer. We will do everything to satisfy your wishes.

model | outside dimensions mm (wxdxh) | HF max. kW | max. sample weight | max. sample size |

|---|---|---|---|---|

O-2.0T | 680 x 680 x 1530 | 2,0 | 15g | Ø 40mm |

O-2.0T-CRS | 680 x 680 x 1530 | 2,0 | 20g | Ø 40mm |

Fast sample preparation for X-ray fluorescence analysis (XRF), ICP und AAS. Melting of small oxydic samples.

Fusion of oxydic materials such as ores, slags, dusts, minerals, refractory materials, etc. in a special Platinum/Gold crucible (95/5%), graphite- or glass carbon crucible by using Lithium-Tetraborate or Sodium-Carbonate. Melting of metal samples up to 20 g.

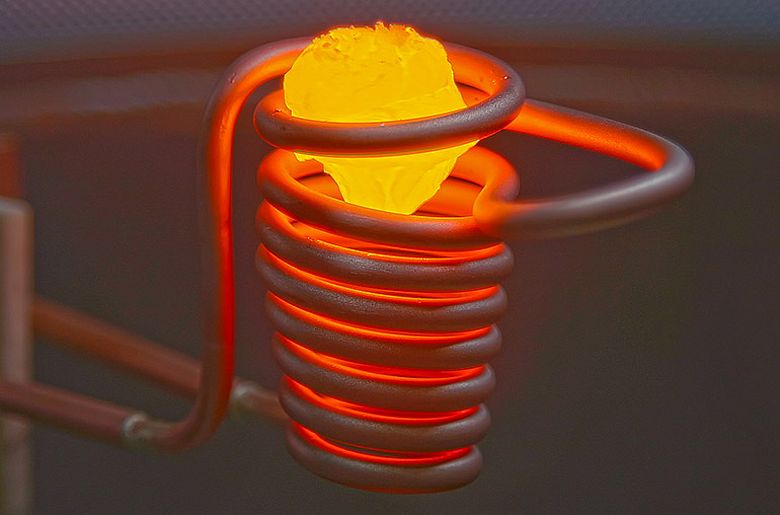

The fusion material in the crucible is inductively heated and fused. The HF-generator transfers a continuously adjustable power output of 100 to 1500 W at 1,5 MHz (penetration depth) to the crucible. Due to the stray field, ponderomotive forces arise in the melt which cause a bath movement and thus guarantee a uniform distribution of the material. Depending on the structure of the material, temperatures up to app. 1500°C can be achieved. The mixing is supported by a motor vibrator which can be switched on when needed. Simultaneously with the crucible, the pouring dish is heated inductively by a flat coil in addition to the melting coil.

The HF-generator with protective cover installed in a solid steel sheet housing is made according to the latest industrial safety and EC guidelines.

The easy removable crucible holding device enables pouring of the fused material without problems. The fusion process can be observed through a blue glass being integrated in the cover. Replacing the induction coil is very easy. When opening the cover, the power is automatically switched off. The inner space is blown off to the back by a fan as protection for the operating staff.

Operation of the furnace is effected by a 7“-color-touch panel with 10 integrated function buttons as well as integrated PLC-function. Decentralized devices are used for the control of the furnace functions.

All inlets and outlets of the sensors and actuators are galvanically separated and the MF/HF is connected fail-safe with the decentralized control unit.

Process data and parameters can be read out via a USB interface.

An easily accessible emergency switch off offers additional safety during operation.

Self-explanatory menu navigation and guided process runs allow an easy operation. The optical display of the process run and the corresponding working steps inform about the current condition of the furnace.

With integrated formula administration for melting programs (number depends on storage volume). The created melting programs can be saved on a USB data carrier and transferred to further furnaces of the same Lifumat model without having to recreate them.

Safety of the various functions is controlled with plain text alarm output as e.g. cooling water temperature, cooling water throughput, cover and door lock, generator current (power). In case of failure and end of casting process, there will be an optical and acoustical signal.

Operating language is available in German or English (other languages against surcharge).

Operating levels (manufacturer, administrator, operator) are locked.

In order to optimize processes as well as created melting programs, the process parameters can be changed freely. With status display of hardware inlets and outlets.

| Product Line: | type series |

|---|---|

| Operation Mode: | Batch and Continuous |

| Construction Types: | Sample preparation unit |

| Designs: | Fusion unit |

| Temperature Max (°C): | |

| Heatings: | electrical |

| Heatingmethods: | induction |

| Atmospheres: | |

| Applications: | fusion, melting, sample preparation for spectroscopy |