AK-model

Productdetails

Innovation and continuous improvement is our mission. To provide our customers with the best applicable solution is our goal.

Linn High Therm is specialized in adapting its products to customer’s requirements. Please let us know if you need any modifications apart from our standard offer. We will do everything to satisfy your wishes.

Model | Liter | Inside dimensions mm (w x d x h) | T. max. °C | Heating power kW |

|---|---|---|---|---|

HK-30* | 31 | 270 x 420 x 270 | 1300 | 7,5 |

HK-40** | 40 | 340 x 500 x 240 | 1300 | 13,5 |

HK-70** | 72 | 400 x 600 x 300 | 1300 | 18,0 |

HK-160 | 160 | 500 x 800 x 400 | 1300 | 26,0 |

HK-315 | 315 | 630 x 1000 x 500 | 1300 | 41,0 |

HK-600 | 600 | 800 x 1300 x 580 | 1300 | 54,0 |

*table unit

**also available as table unit

Furnace housing, housing of separate switch box and swivelling door (to side, in standard version) consist of a lightweight sheet steel construction. The painting with structural lacquer serves as protection against corrosion. The chosen colours blue/white give a nice appearance to the entire furnace.

The rear ventilated brick lining of the furnace consists of high quality lightweight refractory bricks in combination with modern fiber insulation materials which assure a high thermal capacity at low energy consumption.

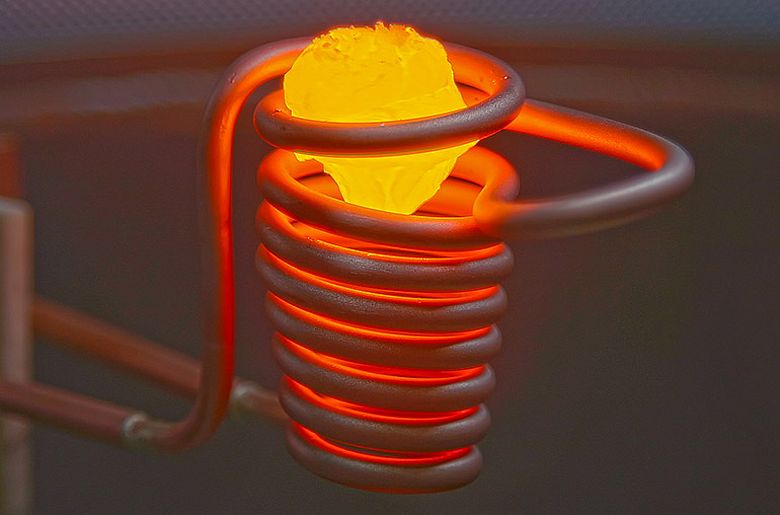

Heating is effected by free radiating Kanthal-A1 respectively APM heating spirals in the rims of the brick lining. The bottom heating is covered with SiC boards. When door is opened, heating is switched off from mains with a safety switch.

The switch and control unit is located in a separate switch box which is connected to the furnace via flexible lines. The furnace is supplied with the following controller:

| Product Line: | type series |

|---|---|

| Operation Mode: | Batch |

| Construction Types: | Furnace |

| Designs: | Chamber furnace |

| Temperature Max (°C): | 1300 |

| Heatings: | electrical |

| Heatingmethods: | resistance |

| Atmospheres: | Air |

| Applications: | borating, forging, hardening, heat treatment, powder carburization, pre-heating, shrink fitting, tempering |