LM-model

Productdetails

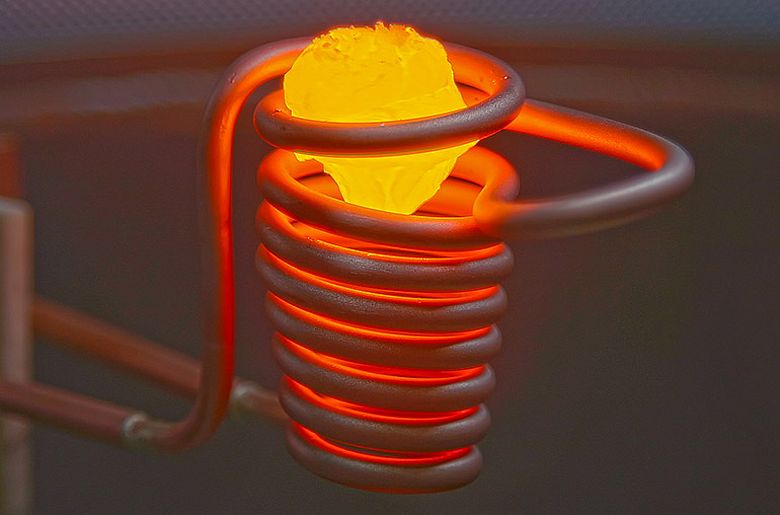

VMK-high temperature-model

Productdetails

Innovation and continuous improvement is our mission. To provide our customers with the best applicable solution is our goal.

Linn High Therm is specialized in adapting its products to customer’s requirements. Please let us know if you need any modifications apart from our standard offer. We will do everything to satisfy your wishes.

model | liters | Inside dimension in mm (wxdxh) | T. max °C | kW |

VMK-10 | 1,0 | 100 x 100 x 100 | 1200 | 0,6 |

VMK-22 | 2,2 | 130 x 170 x 100 | 1200 | 0,9 |

VMK-39 | 3,9 | 180 x 200 x 110 | 1200 | 1,3 |

VMK-80 | 7,7 | 210 x 230 x 160 | 1200 | 2,1 |

VMK-135 | 13,5 | 250 x 300 x 180 | 1200 | 2,6 |

VMK-250 | 25,0 | 250 x 400 x 250 | 1200 | 3,75 |

In order to avoid corrosion in case of, e.g. ashing, combustion, digestion or aggressive binders, the VMK-furnaces are installed in a stainless steel housing. Below the door there is a shelf made of stainless steel, which also protects the operating elements from thermal and mechanical damage. Exhaust connecting piece made of stainless steel is installed at the rear wall.

The furnace chamber is vacuum formed in one ceramic fiber block. That way high insulation values can be achieved which result in a considerable reduction of the wall thickness of the insulation as well as of the weight at low energy saving volume. A stable, finned ceramic plate in the furnace bottom guarantees easy charging.

Long-live Kanthal A1 heating elements are embedded in the fiber muffle. The heating is effected from three sides so that a uniform temperature distribution in the furnace chamber is achieved. In connection with the insulation, faster heating and cooling cycles are obtained as well as energy saving of app. 40 %.

The control system is installed on the bottom side of the furnace (below the deposit) and as a standard it is equipped with the following instruments:

| Product Line: | type series |

|---|---|

| Operation Mode: | Batch |

| Construction Types: | Furnace |

| Designs: | Chamber furnace, Laboratory furnace |

| Temperature Max (°C): | 1200 |

| Heatings: | electrical |

| Heatingmethods: | resistance |

| Atmospheres: | Air, Controlled gas atmosphere |

| Applications: | annealing, ashing, calcination, calibration, curing, debinding, drying, firing, fusion, glueing, hardening, heat treatment, melting, oxydation, pre-heating, shrink fitting, sintering, stress-relieving, tempering |