Innovation and continuous improvement is our mission. To provide our customers with the best applicable solution is our goal.

Linn High Therm is specialized in adapting its products to customer’s requirements. Please let us know if you need any modifications apart from our standard offer. We will do everything to satisfy your wishes.

Model | Liter | T. max in °C | Inside dimenisons mm (wxdxh) | kW |

KS-80-Vac | 61 | 1050/1200** | 320 x 600 x 320 | 18,0 |

KS-160-Vac | 149 | 1050/1200** | 410 x 700 x 520 | 25,0 |

KS-240-Vac | 233 | 1050/1200** | 470 x 800 x 620 | 40,0 |

KS-480-Vac | 436 | 1050/1200** | 560 x 950 x 820 | 51,0 |

*Customer specific KS-Vac up to 1 m³

**1200°C optionally + higher heating power

Furnace housing and housing of the separate switch cabinet consist of a lightweight steel sheet construction. The painting with structural lacquer serves as protection against corrosion. The chosen colours blue/white give a nice appearance to the entire furnace.

The furnace is manufactured with high quality lightweight refractory bricks (sides, rear wall, bottom). The additional heat insulation with calcium silicate boards guarantees high thermal power at low energy consumption. The removable ceiling is insulated with fiber modules.

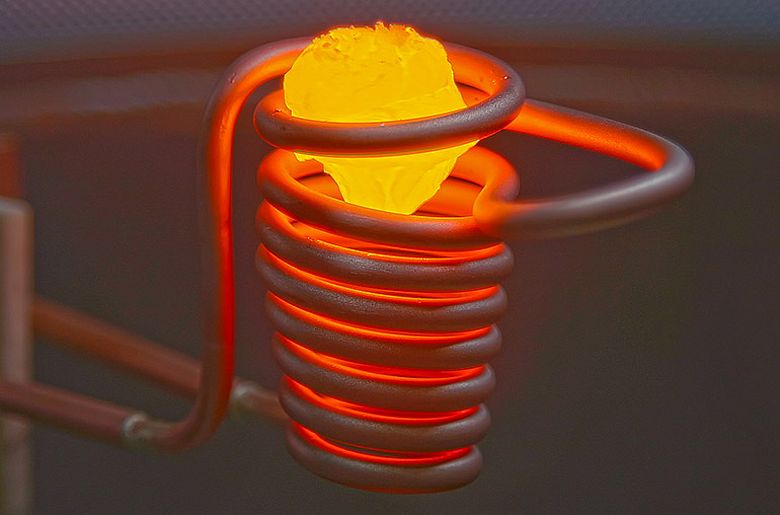

The heating is effected by free radiating CrFeAl heating spirals (hair pins) in rims of the brick lining (2 side walls, bottom and door).

All heat coated parts of the muffle insert are made of heat resistant material or made of stainless steel and are firmly fixed on the front side of the furnace by supporting angles. Furthermore, the muffle insert is movable in the furnace chamber so that it can expand to the back side. Due to a stainless steel chimney installed between muffle cooling frame and outer housing, an air stream develops which cools the muffle already before the cooling frame. This furnace can be operated with insert muffle only.

The door is designed as a swivelling door plug with radiation sheets. On the front side of the muffle insert, a stainless steel rectangular tube frame is welded on. This frame is water cooled and serves as sealing flange. The water cooled swivelling door is equipped with a special silicone sealing.

Gas inlet and gas outlet are led out on the furnace rear wall, water supply and discharge pipes are led to backside of the furnace sideways.

The vacuum flange is led out sideways between muffle cooling frame and furnace front side.

The switch and control system is installed in a separate switching part which is connected with the furnace via flexible lines. The furnace will be supplied with the following components:

1 temperature controller G 400

1 safety controller for switch-off of over temperature

1 load relay

2 thermocouples located in the muffle insert (control thermocouple) and between muffle insert and furnace heating (safety thermocouple)

| Product Line: | type series |

|---|---|

| Operation Mode: | Batch |

| Construction Types: | Furnace |

| Designs: | Chamber furnace |

| Temperature Max (°C): | 1200 |

| Heatings: | electrical |

| Heatingmethods: | resistance |

| Atmospheres: | Air, Controlled gas atmosphere, Vacuum |

| Applications: | annealing, ashing, borating, brazing, bright annealing, calcination, carburization, debinding, dewaxing, graphitization/carbonisation, heat treatment, nitriding, nitrocarburizing, reduction, sintering, soldering, stress-relieving, surface coating, tempering |