Supercast-model

Productdetails

Titancast-model

Productdetails

Innovation and continuous improvement is our mission. To provide our customers with the best applicable solution is our goal.

Linn High Therm is specialized in adapting its products to customer’s requirements. Please let us know if you need any modifications apart from our standard offer. We will do everything to satisfy your wishes.

Model | Platicast-600T | Platicast-600T-Vac |

|---|---|---|

Dimensions (w x d x h) | 920 x 900 x 1500 | 920 x 900 x 1500 |

Weight (kg) | 320 | 360 |

Mains connection (V/Hz/Ph) | 400 / 50 / 3 | 400 / 50 / 3 |

Mains supply at full charge (kVA) | 14,0 | 14,0 |

Output power (kW) | 6,6 | 6,6 |

Nominal frequency (MHz) | 1,2 | 1,0 |

Cooling water need (l/min 3,5 bar) | 8 | 8 |

Vacuum system max. Vac | - | 1 mbar |

Rotary vane pump | - | x |

Protective gas purging | x | x |

Revolutions casting arm (max. U/min-1) | 500 | 500 |

Muffle size (max. Ø x lg) | 130 x 195 | 130 x 195 |

|

|

|

Other dimensions and special voltages on request | ||

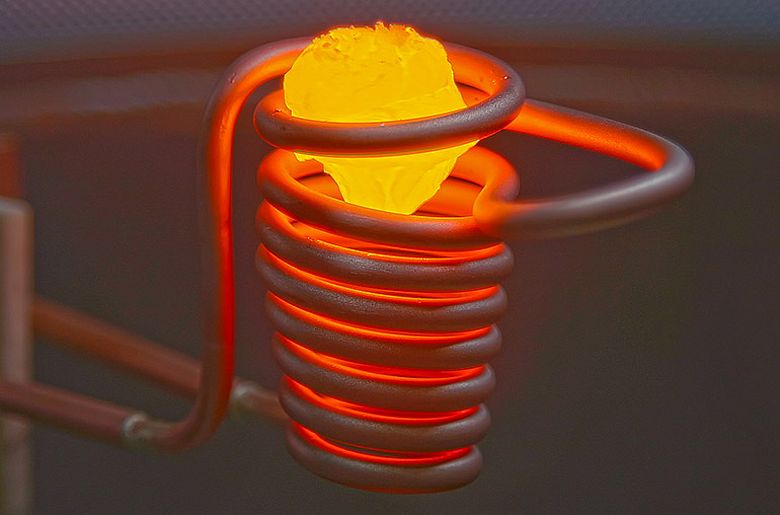

The machine consists of a fitted with noise suppression high frequency generator with an induction coil power of appr. 6,6 kW and an operating frequency of appr. 1,0 to 1,2 MHz which is mounted together with the under atmosphere or vacuum or vacuum with protective gas purging, working induction melting furnace and centrifugal casting device in a compact, two times lacquered, stainless steel housing. The required space is appr. 1,0 m². (without additional devices).

The operation is effected through a 7“ colour-Touchpanel with 10 integrated function keys and integrated SPS function. Local components are used for control of machine functions.

All inlet and outlets of the sensors and actuators are galvanically separated and MF/HF is fail-safe connected with the local control unit.

The process datas and parameters can be read out over an USB interface.

A well accessible emergency switch off offers additional safety in operation.

The self explanatory menu navigation and guided programme processes make a simple operation possible. The optical display of the programme process and the respective working steps inform about the current state of the machine.

With integrated recipe administration for the melting programmes (the number depends on storage). The compiled melting programmes can be saved on a USB storage medium and and levelled to all further machines of same Lifumat type, without having to compile it new.

The safety supervision of diverse functions is effected with clear text alarm f.ex. cooling water temperature, cooling water flow, cover and door locking, generator stream (power). An optic and acoustic signal is effected at disturbance and casting process end.

Operator language is selectable in German or English (further against surcharge).

The user levels (producer, administrator, operator) are locked.

In order to optimize processes and written melting programmes the process parameters are freely changeable. With status display of hardware inlet and outlet.

With switch off automatic appr. 8 l/min. at at least 3,5 bar, max. 5 bar, at a water temperature of max. 25°C. When using of deionized tube water max. hardening degree 6° German hardness, conductivity max. 200 µS/cm.

Selectable as melting or casting atmosphere respectively:

A vacuum of max. 1 mbar is reachable with rotary vane pump with 4 m³/h. The pump is not integrated in the machine housing but will be placed next to the machine.

Platinum | 600 g |

German silver | 1000 g |

Palladium | 1000 g |

Bronze | 1000 g |

Gold | 1200 g |

Copper | 1000 g |

Silver | 1000 g |

Brass | 1000 g |

CrNi-Steel | 800 g |

| Product Line: | type series |

|---|---|

| Operation Mode: | Batch |

| Construction Types: | Casting unit, Melting unit, Precision fince casting system |

| Designs: | Casting unit, Precision fine casting system, Remelting unit |

| Temperature Max (°C): | 2000 |

| Heatings: | electrical |

| Heatingmethods: | induction |

| Atmospheres: | Controlled gas atmosphere, Vacuum |

| Applications: | casting, melting, precision fine casting |