MFG-model

Productdetails

Platicast-model

Productdetails

Titancast-model

Productdetails

Innovation and continuous improvement is our mission. To provide our customers with the best applicable solution is our goal.

Linn High Therm is specialized in adapting its products to customer’s requirements. Please let us know if you need any modifications apart from our standard offer. We will do everything to satisfy your wishes.

| Supercast | Supercast- Vac | Supercast- Titan/TiAl |

|---|---|---|---|

Dimensions mm (w x d x h) | 500x600x1900 (MF-inverter) 1800x1500x2700 (casting machine) 1000x600x2400 (switching unit)

| ||

Weight (kg) | 1550 | 1650 | 1750 |

Mains supply (V/Hz/Ph) | 400/50/3 | 400/50/3 | 400/50/3 |

Mains input at full load | 28 | 28 | 38 |

Output power (kW) | 20 | 20 | 30 |

Nominal frequency (kHz) | 20 | 20 | 20 |

Water consumption (l/min 3,5 bar) | 15 | 15 | 20 |

Vaccumsystem max. Vac (mbar) | - | 5x10-1 | 5x10-3 |

Roots pump | - | - | x |

Protective gas flushing | x | x | x |

Speed of casting arm (max. U/min-1) | 300 | 300 | 300 |

Muffle size (max. Ø x lg) | 200 x 350 | 200 x 350 | 200 x 350 |

Other dimensions and special voltages upon request. |

| ||

The housing consists of a stable profile steel / sheet steel construction. As protection against corrosion serves the color with structure lacquer (blue/light grey). The casting shell is covered by a hinged housing cover, which allows the charging of the casting arm. In the housing-cover an inspection glass of clear quartz glass und a movable blue glass as protection are installed, which is mounted above. On the upper side of the housing is installed a control desk with control elements and a SIMATIC Touch Panel.

The casting arm is designed, so that the hinged cover closes the casting chamber. The useable volume has a length of 350 mm, a width of 200 mm and a height of 220 mm.

The unbalance of the casting arm can be easily removed by adjustable counter weights.

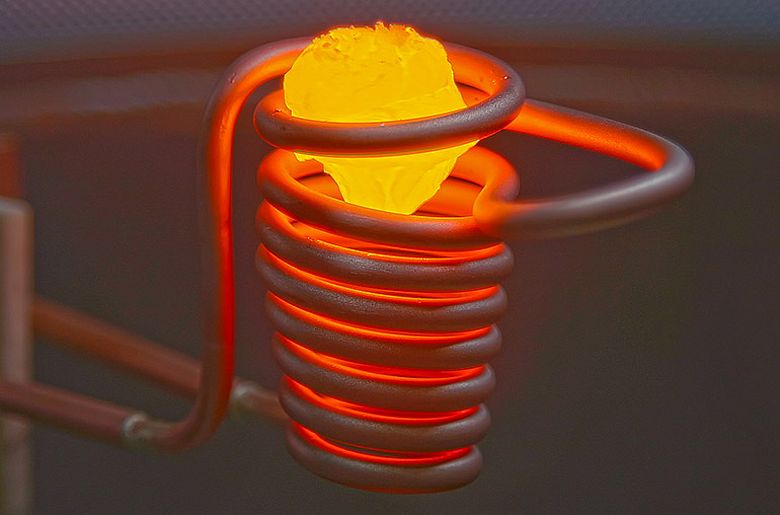

During the total melting process the metal can be watched through inspection glass made of quartz glass, which is installed in the casting arm. At the same time the temperature of the metal is measured through this inspection glass by an optical spectral pyrometer. The signal of pyrometer is displayed as video signal, what eases the observation of the melt and is available as option.

On the underside of the casting arm a quartz glass crucible is provided, which separates the interior chamber for the casting arm off the atmosphere. The connection between quartz glass crucible and casting arm is assured by a temperature resistant sealing. Cooling vanes are installed on the housing of the casting arm for cooling of the housing. An aluminium-alloy is used for better cooling of the housing of the casting arm.

The melting temperature and therefore the moment of the cast is recorded and controlled by a temperature measuring device (option) with a measuring range selectable from 900-2300°C. The temperature measuring device is mounted on the frame of the casting machine.

The S7 SPS, which is installed in the control cabinet, controls the whole casting process and observes the existing safety devices.

All electrical function groups are arranged on the control cabinet and are easily accessible and exchangeable.

Via a SIMATIC Touch Panel TB 170B blue mode in the control panel the pre-adjusted (adapted to the part to be cast and reproducible by 100%) casting parameters can be read as well as execution of the operation of the system.

The control is free programmable, in order to do changes without any problems and the machine can be adapted to amplified applications.

The casting arm is designed as vacuum- and gas tight casting chamber. With the vacuum casting arm it is possible to work under air atmosphere, under vacuum or under vacuum with following protective gas flushing at low underpressure, what is a big advantage for alloys with a high vapour pressure or alloys which easily oxidize.

Selector buttons on the control panel adjust the casting atmosphere.

The casting atmosphere is adjusted on the control panel via selection switch. As protective gases we recommend N2, Ar or forming gases with a H2 content of max. 5%

The casting arm is operated via a special three phase motor, which is controlled by a frequency converter. The motor has a high torque over the whole rpm-range and the run-up time is infinitely variable by control software.

The torque is conferred to the quill shaft via a tooth wheel and tooth belt with toothed belt disc of the casting arm.

A door tumbler according to EN292, EN953 and EN1088 locks and controls the housing cover and the doors of the casting machine during the melting and casting process. It is warranted by the safety switching that the cover of the casting arm and the door does not inadvertently open during the casting process (as long as the casting arm rotates) and nobody can get injured.

For safety reasons the melting program can only be started when the top of casting arm is closed. As soon as the top is open during the melting program, the program stops automatically and the power of the furnace is shut down.

Two air-water heat exchangers cool the interior of the casting machine and prevent that the machine is thermal overloaded. A shutdown of the cooling water of the coil prevents damage of the machine in case of breakthrough of the coil. The pressure of the protective gas and the compressed air is continuously monitored and in case of shortfall of a programmable value, a fault message is issued.

It is possible to use cuvettes with a max. diameter of 180 mm, a max. length of 350 mm and a max. weight of 14 kg. Of course, it is possible to use any standard cuvettes with the corresponding holders.

| Product Line: | type series |

|---|---|

| Operation Mode: | Batch |

| Construction Types: | Casting unit, Melting unit, Precision fince casting system |

| Designs: | Casting unit, Precision fine casting system, Remelting unit |

| Temperature Max (°C): | |

| Heatings: | electrical |

| Heatingmethods: | induction |

| Atmospheres: | Controlled gas atmosphere, Vacuum |

| Applications: | casting, melting, precision fine casting, sample preparation for spectroscopy |