FRH-3-150/1000/1250 Bifilar

Productdetails

FRH-3-250/1750/850

Productdetails

Innovation and continuous improvement is our mission. To provide our customers with the best applicable solution is our goal.

Linn High Therm is specialized in adapting its products to customer’s requirements. Please let us know if you need any modifications apart from our standard offer. We will do everything to satisfy your wishes.

SIZES

Type | T. max. °C | zones | inner-Ø | Heated length mm | kW |

|---|---|---|---|---|---|

FRH-25/150/1100 | 1150 | 1 | 25 | 150 | 0,25 |

FRH-40/250/1100 | 1150 | 1 | 40 | 250 | 0,60 |

FRH-40/500/1100 | 1150 | 1 | 40 | 500 | 1,20 |

FRH-70/250/1100 | 1150 | 1 | 70 | 250 | 0,90 |

FRH-70/500/1100 | 1150 | 1 | 70 | 500 | 1,80 |

FRH-100/500/1100 | 1150 | 1 | 100 | 500 | 2,60 |

FRH-40/220/1250 | 1300 | 1 | 40 | 220 | 0,86 |

FRH-40/520/1250 | 1300 | 1 | 40 | 520 | 1,35 |

FRH-70/520/1250 | 1300 | 1 | 70 | 520 | 2,22 |

FRH-100/520/1250 | 1300 | 1 | 100 | 520 | 2,88 |

FRH-3-40/750/1100 | 1200 | 3 | 40 | 750 | 1,80 |

FRH-3-70/750/1100 | 1150 | 3 | 70 | 750 | 2,70 |

FRH-3-100/1000/1100 | 1150 | 3 | 100 | 1000 | 5,20 |

FRH-3-150/1000/1100 | 1150 | 3 | 150 | 1000 | 7,60 |

FRH-3-40/750/1250 | 1300 | 3 | 40 | 750 | 2,77 |

FRH-3-70/1000/1250 | 1300 | 3 | 70 | 1000 | 5,02 |

FRH-3-100/1000/1250 | 1300 | 3 | 100 | 1000 | 7,08 |

FRH-3-150/1000/1250 | 1300 | 3 | 150 | 1000 | 9,50 |

FRH-40/250/1550 | 1600 | 1 | 40 | 250 | 1,60 |

FRH-40/500/1550 | 1600 | 1 | 40 | 500 | 3,00 |

FRH-67/250/1550 | 1600 | 1 | 67 | 250 | 2,40 |

FRH-67/500/1550 | 1600 | 1 | 67 | 500 | 4,80 |

Also available as tilted version FRHT / also available as vertical version FRV/FRVT. | |||||

The furnace housing consists of a stainless steel construction and is placed on an underframe. The furnace is characterized by an operating friendly design.

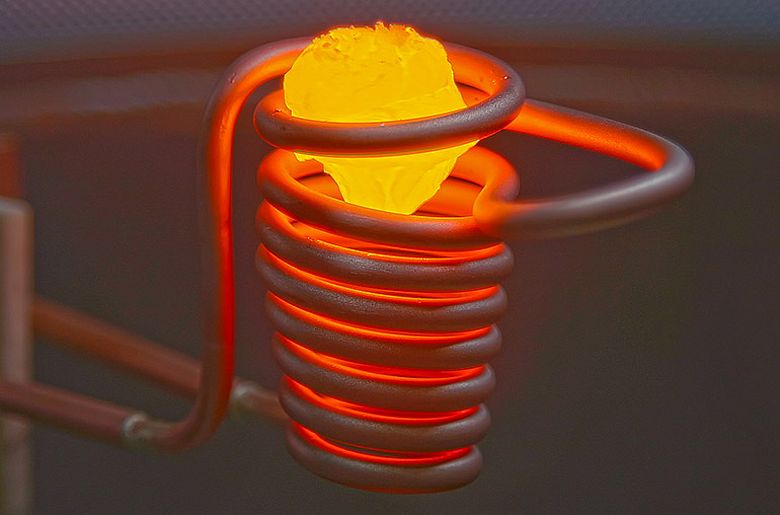

The insulation exclusively consists of energy saving fiber material. A ceramic wool module with embedded heating coils respectively slotted SiC tube (1575°C) and corresponding end plates is used. Thin-walled, low heat storing materials enable extremely short heating up and cooling down cycles. Due to a circulating air layer between insulation and sheet metal housing, low outside wall temperatures are reached.

The furnace is heated with embedded Kanthal heating coils. They are fixed on the inner diameter of the heating tube and can optionally be switched in three zones. The heating elements are operated by transformers and electronic load relays/thyristor controller. This tube furnace disposes of a power reserve in order to be able to reach the desired temperature and control accuracy.

Each 1 PtRh-Pt thermocouple (accuracy: class 2 according to DIN IEC 584 part 2) respectively NiCr-Ni thermocouple (1150°C) is installed in the middle and in one of the outer heating zones and is led to the corresponding temperature controller. The thermocouples are inserted between two windings of the heating element and look into the useful chamber by app. 5 mm.

The switch and control unit with power part is installed in a separate housing and is connected with the tube furnace by flexible lines (1 to 1,5 mm). Among other things, the control unit is equipped with minimum one temperature controller G 400.

| Product Line: | type series |

|---|---|

| Operation Mode: | Batch |

| Construction Types: | Furnace |

| Designs: | Bell type furnace, Bottom loader furnace, Crucible furnace, Laboratory furnace, Push-through furnace, Shaft furnace, Tube furnace |

| Temperature Max (°C): | 1800 |

| Heatings: | electrical |

| Heatingmethods: | resistance |

| Atmospheres: | Air, Controlled gas atmosphere, Overpressure, Vacuum |

| Applications: | activation, ashing, brazing, bright annealing, calcination, calibration, carburization, crystal growing, curing, CVD chemical vapour deposition, debinding, directional solidification, firing, fusion, gemstone heat treatment, heat treatment, melting, pulling, reduction, shrink fitting, sintering, soldering, stress-relieving, surface coating, tempering |