MKE-model

Productdetails

Innovation and continuous improvement is our mission. To provide our customers with the best applicable solution is our goal.

Linn High Therm is specialized in adapting its products to customer’s requirements. Please let us know if you need any modifications apart from our standard offer. We will do everything to satisfy your wishes.

Model | MKH-2,7 | MKH-5,4 | MKH-7,2 |

|---|---|---|---|

Outside dimensions furnace (W x D x H) | 800 x 800 x 1200 | 800 x 800 x 1200 | 1600 x 1000 x 1400 |

Outside dimensions control housing (W x Dx H) | 1000 x 500 x 700 | 800 x 600 x 2300 | 800 x 800 x 2300 |

Useful volume (Liter) | 2,4 | 2,4 | 27 |

Chamber volume (Liter) | 35 | 46 | 156 |

Microwave power (kW) | 2,7 | 5,4 | 7,2 |

Operating frequency (GHz) | 2,45 | 2,45 | 2,45 |

Power supply | 400 V/3 Phases/N/ PE/ 50 Hz | 400 V/3 Phases/N/ PE/ 50 Hz | 400 V/3 Phases/ N/ PE/ 50 Hz |

Connection power max. (kVA) | 6,0 | 10,4 | 14,0 |

The furnace was concipated above all for the special requirements in scientific and industrial area – and here especially in terms of high temperatures.

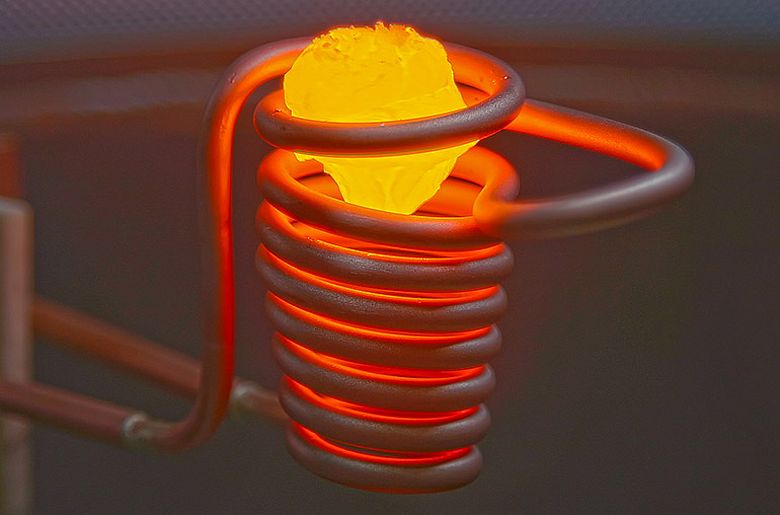

Due to size, material and type of microwave coupling, the machine has excellent power distribution compared to usual microwave furnaces. High-Q-chamber, alternative atmospheres (option), safety qualities and size contribute to the ideal application in science and industry.

The standard furnace will be controlled manually. With the different options test series can be carried out which require reproducible conditions, exact sample temperatures and defined temperature time curves.

Critical zones are equipped with thermal safety switches for protection of microwave generators. Additional safety devices are installed in the furnace like f.ex. an automatic power interruption when opening the door through two safety switches.

A Microwave sealing that is installed in the door offers optimal safety against emerging microwave radiation.

The reachable product temperatures depend on the power, sample material, form and size, position of samples, susceptors (material, size, position) and many other factors. Therefore a general statement regarding reachable product temperatures cannot be made. The maximal product temperature will be restricted through the max. operating temperature of the insulation. This is 1700°C continuous operation (insulations with higher operating temperatures see options).

In order to heat sample materials which have bad coupling qualities at room temperature, it will be needed microwave susceptors for indirect sample preheating (see options).

The microwave power will be generated through independent 900 W magnetrons. The microwave power is continuously adjustable from 15% - 100%.

The magnetrons are air cooled in order to ensure, with minimal effort, an optimal cooling in continuous operation.

The actual furnace housing made of stainless steel is installed touch safe in the outer housing so that also at continuous operation the wall temperature of the outer housing remains relatively low (max. 40°C above ambient temperature), except on the door front board.

The swivelling door (Front-loader) with microwave sealing is equipped with turn locking (spring pressure resistance). Current connections are installed on the rear side of the furnace.

The door frame, viewing window (option), pyrometer window and waveguide flanges (only with option gas or vacuum tight chamber) are watercooled.

The inner housing is lined with special ceramic insulation boards. The use of this lightweight, low heat storage insulation material permits extremely short heating and cooling times. The max. operating temperature is 1700°C for continuous operation, short time up to 1700°C.

The following components are essentially installed in a furnace part that is connected to the control housing (cable length 3 m, other length on request):

| Product Line: | type series |

|---|---|

| Operation Mode: | Batch |

| Construction Types: | Furnace |

| Designs: | Chamber furnace, Laboratory furnace |

| Temperature Max (°C): | 1800 |

| Heatings: | electrical |

| Heatingmethods: | microwave/dielectric |

| Atmospheres: | Air, Controlled gas atmosphere, Vacuum |

| Applications: | ashing, calcination, melting, sintering |